Sahibabad Industrial Area Site 4, UP

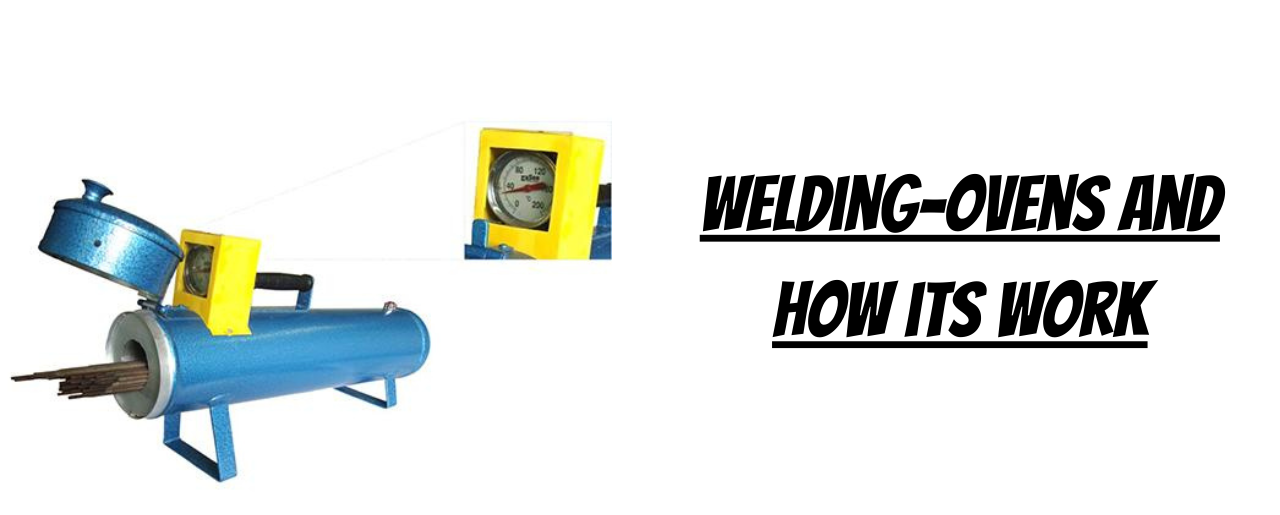

welding-ovens and how its work

Welding ovens, also known as welding rod ovens or electrode ovens, are used to store and condition welding electrodes or rods. These electrodes are used in various welding processes, such as shielded metal arc welding (SMAW) or stick welding.

Welding ovens, also known as welding rod ovens or electrode ovens, are used to store and condition welding electrodes or rods. These electrodes are used in various welding processes, such as shielded metal arc welding (SMAW) or stick welding. Welding ovens are designed to keep the electrodes dry and free from moisture, which can adversely affect their performance and quality of welds.

Here's how welding ovens typically work:

-

Storage and Protection: Welding electrodes are stored in sealed containers or vacuum-sealed packaging to prevent moisture absorption. However, when the packages are opened, the electrodes start to absorb moisture from the surrounding air.

-

Oven Heating: The welding oven consists of an insulated chamber made of metal or other heat-resistant materials. Inside the oven, there are heating elements that generate heat to raise the temperature within the oven.

-

Temperature Control: Welding ovens usually have a thermostat or temperature controller to regulate the internal temperature. The desired temperature range for storing welding electrodes is typically between 250°F (121°C) and 400°F (204°C), depending on the specific type of electrode.

-

Moisture Removal: As the oven heats up, the increased temperature helps remove moisture from the welding electrodes. The heat causes the moisture to evaporate, and the oven's insulation helps retain a low humidity environment within the oven.

-

Time Duration: The time required to dry the electrodes depends on factors such as the initial moisture content, electrode size, and oven temperature. Typically, electrodes are recommended to be stored in the oven for a specific duration to ensure proper drying.

-

Welding Preparation: Once the welding electrodes have been stored in the oven for the recommended time, they are considered dry and ready for use. The welder can remove the electrodes from the oven and transfer them to a storage container or directly to the welding machine.

It's important to note that different types of welding electrodes may have specific drying requirements, so it's essential to refer to the manufacturer's guidelines for proper usage and storage.

Welding ovens are particularly useful in humid environments or when welding critical applications where moisture control is crucial to maintain weld quality and prevent defects. By using welding ovens, welders can ensure that their electrodes are properly conditioned and ready for optimal welding performance.